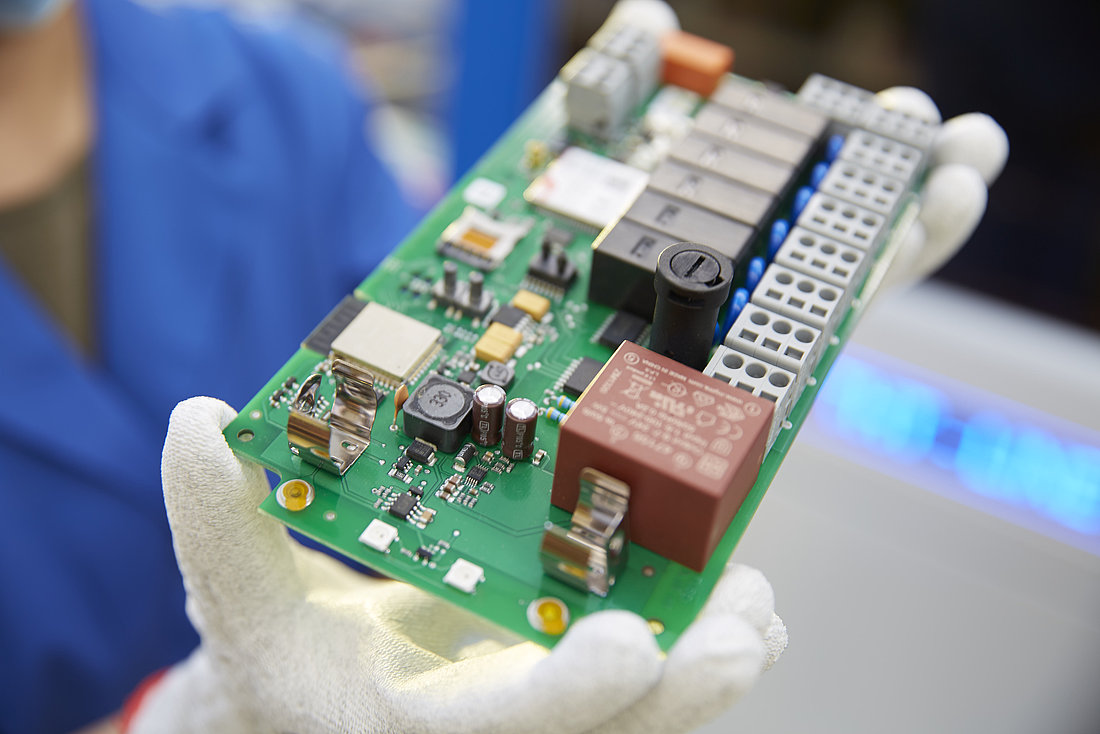

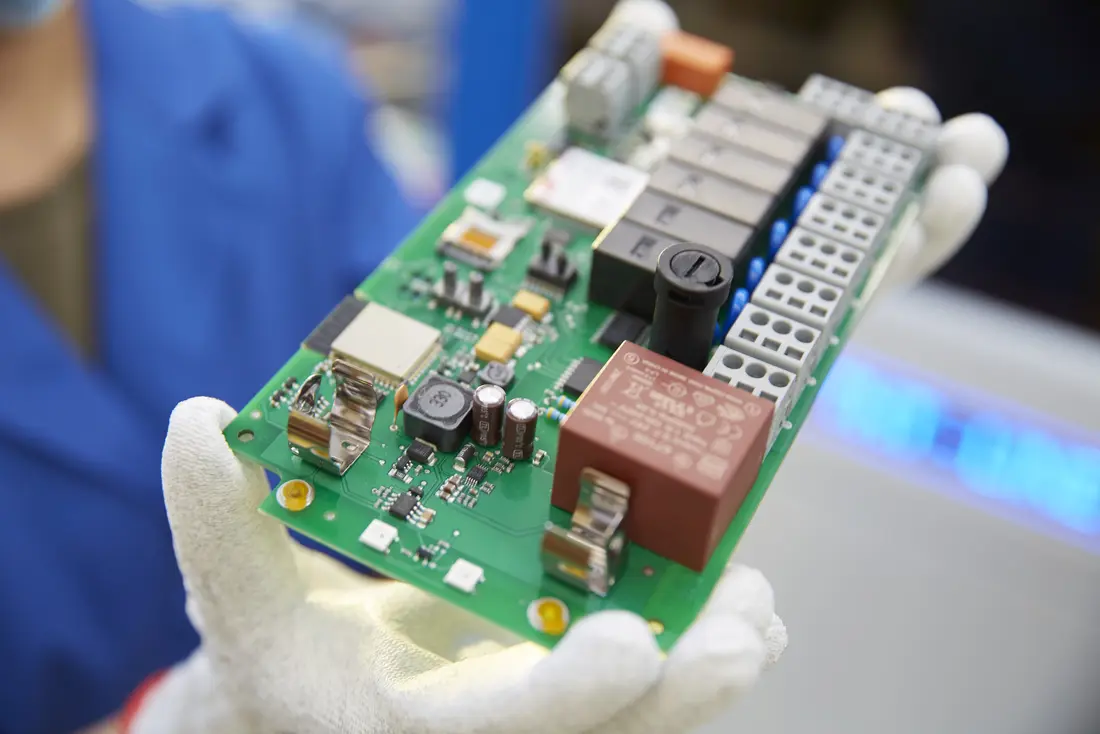

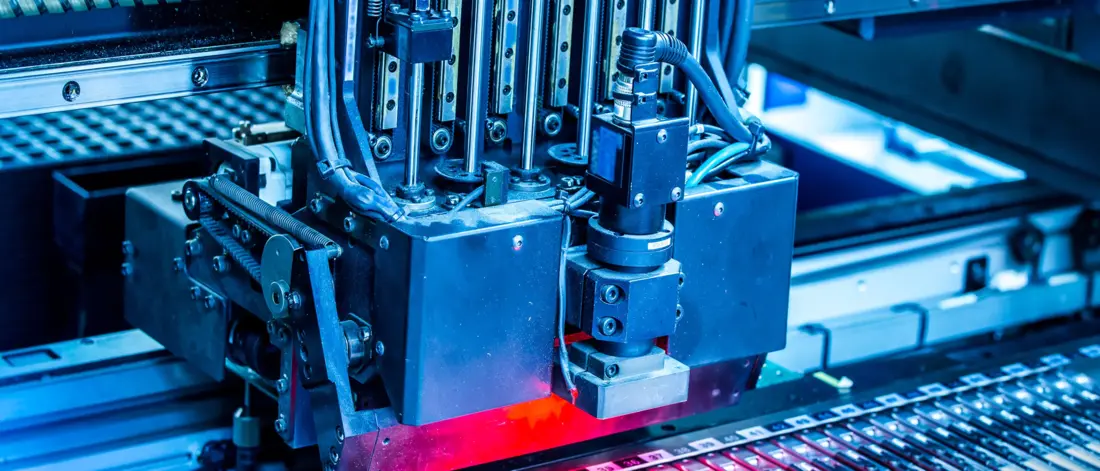

As far as possible, we make use of standardised and proven modules developed and produced by us, which we supplement with customer-specific components. This platform concept allows optimised solutions to be created for a competitive price. Our systematic approach as early as the development phase ensures short development times plus high flexibility, thereby cutting development costs and boosting product quality. This applies equally for hardware and software. As manufacturer of electronic components, we are a competent partner for demanding, customer-specific solutions.

Along with our know-how, our customers rely on the optimised module and platform development technology we can supply. Whatever controls your industrial application needs: We implement your requirements professionally and precisely to provide an individual control solution.

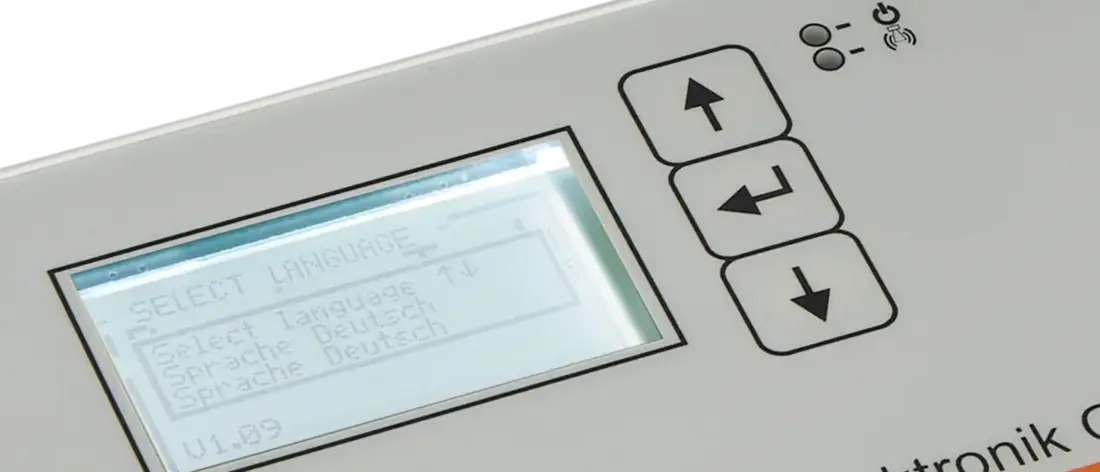

Customer-specific housings

We develop and build control systems – precisely to your wishes and requirements. Control systems not only require electronics, but also a housing adapted to your needs. Together with you, we design and build your specific plastic or metal housing. From adapted standard housings to customer-specifically developed injection moulded housings – whether a control cabinet or individual sheet metal housing – we find the optimum solution for you and with you.